sheet metal drawing standards

ANSI Y1472-1978 Gear and Spline Drawing Standards Part 2. This video demonstrates how to properly dimension a sheet metal layout technical drawing.

Freelance Sheet Metal Design Services For Companies Cad Crowd

Most-Recent Revision Only 260 Not False 0 Publisher.

. Sheet Metal Drawing Standards. Sheet metal shops can bend to tolerances of 015 or 04mm. 216 For slots callouts for CENT TYP and RADIUS or R are assumed.

However once you expand over all four bends that number increases to a difference of 130 on the overall flat length of the part. 2015 and AS 9102. Your tolerances to and from bends should reflect this.

Bevel and Hypoid Gears ASME B4612002 Surface Texture Surface Roughness Waviness and Lay. 10 Pack 6 X 1 Hex Washer Head Self Drilling Screws Zinc. It shall be equal to three times of sheet thickness plus bend radius.

Foils sheets and plates are pretty much the same with the only difference being in thickness. 4 FILE STRUCTURE 41 Sheet Numbering There are three components that make up the sheet numbers. This specification details the requirements for water based drawing compounds that provide additional lubricity to aid in metal forming operations and must be compatible with current production.

Offsets should follow the same sheet metal design guidelines as other bends. When considering sheet metal thickness a single sheet with punches holes is a good rule of thumb. This makes low carbon steel a more cost-eective choice.

Two New Short Radius Standards Four New Concrete Barriers One New AREF-21 Standard One. High are usually used for dimensions. I have never checked the accuracy of the punching or laser cutting or whatever.

The Sheet Metal Parameters dialog box is displayed. The radius of an inside bend should be at least equivalent to the materials thickness to avoid fractures or distortion. Fractions should be as large as whole numbers and care should be taken to see that the figures do not touch the dividing line.

To the left of the title block touching the bottom border line and the title block. Above the title block touching the right border line and the title block 4. Packaging Drawings Not Available 21.

We identified it from well-behaved source. The variation becomes larger as the bend angle increases and the part will no longer pass inspection. REQUIREMENTS FOR SHEET METAL PART DRAWINGS Sheet metal parts are typically created from material less than 250 inches thick and are formed by folding the material at specific locations with a controlled bend radius.

Abbreviations March 2008. Many sheet metal workers are educated and certified in two popular standards --ISO 9001. Minimum Sheet Metal Flange Bend Length 3 x Sheet Thickness Bend Radius.

FROM NOVEMBER 2000 TO PRESENT. I do lots of sheet metal drawings. Above 24 inches practice varies but in general feet and inches are used as 3-2½ for 3 feet 2½ inches.

The Standard Review Committee SRC was established to review revise and update standards and documents. Lower-left corner of the drawing sheet touching the left and bottom border lines 3. It reviews general dimension standards as well as requirements for.

I assume they are pretty good. This gives brass sheet a wider range of performance depending on end use of the designed part. Be bound to the drawings.

ASTM 11 SMACNA 9 MPIF 11 ICBO 1. But what makes these guidelines so beneficial to customers like you. Sheet metal is any metal that has a thickness in between 056 millimetres.

The discipline designator the sheet type designator and the sheet sequence number. 215 On detail drawings with 3 or more hole sizes holes shall be tabulated using the label shown. Millimetres Mils Gauge.

January 1 2020 - GMNA. BRASS Low carbon steel contains 005-032 carbon compared to medium high and ultra-high carbon steel. 8 am to 3 pm.

1002 Washington Ave 2nd Floor. Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula. Depending on the quantity of zinc in the alloy.

MEMORANDUMS OF ISSUED REVISED STANDARDS. We receive this nice of Sheet Metal Drawing Standards graphic could possibly be the most trending topic in imitation of we. For low carbon steel the minimum radius can be ½ the sheet thickness or 080 mm 003 whichever is greater.

Narrow Your Results Revision. 9981870 - Drawing Compounds Water Based for Sheet Metal. These factors all play a role in why most manufacturers dont want you to dimension parts in the flat pattern.

We typically use C2680 for sheet metal forming. Drawing upon the considerable experience of its own CADD Task Force. Drawing Change Procedure March 2008 24.

Sheet metal is one of the shapes and forms metal can be bought in. Defining the Sheet Metal Parameters This task shows you how to configure the sheet metal parameters. Why ISO Matters in Custom Metal Fabrication 1.

All University of Houston project sheets shall follow the sheet numbering standards described below. A description is not available for this item. Most-Recent Revision Only Clear all.

Asme Sheet Metal Standards Briefly Discuss How The Term Precision Sheet Metal. Sheet Metal Drawing Standards 21-40 of 260 results 20 results per page 10 results per page 30 results per page 50 results per page 100 results per page Filters. Sheet Metal Drawing Standards.

Select the Bend Extremities tab. Sheet Metal March 2008 22. Here are a number of highest rated Sheet Metal Drawing Standards pictures on internet.

2 Scope The intent of this specification is to supplement all engineering drawings blueprints and customer specifications. Click the Sheet Metal Parameters icon. Enter 1mm in the Thickness field.

Standard in which case AS SHOWN should be noted on the drawing. Enter 5mm in the Default Bend Radius field. SCS articulates the CAD standards that will enable SMACNA members and the rest of the AEC community to apply CAD effectively to mechanical fire protection and plumbing design and construction.

Upper-left corner of the drawing sheet touching the top and left border lines 2. The minimum recommended sheet metal flange bend length avoid cracks in the bending area. Its submitted by dealing out in the best field.

A alphabetical character. There are other measurement units used to categorise metals by thickness though. Vertical figures about ⅛ in.

Asme pipe labeling standards. Two New Crash Cushion Standards and Two New Steel Barriers Applicable December 2021. Public input and participation is requested by the submittal of proposals for suggested.

Electrical and Electronics Drawings March 2008 23. D 25T R see below The height can be less but it required secondary operations and is far more costly. 214 All tapped holes are assumed to have coarse threads unless otherwise specified.

I am not aware of standards for them separate from any other kind of fabrication drawing. Generally capabilities of of 09mm 20mm in thickness are able to be manufactured from sheet 3mm but this tolerance depends mainly on the part. If your order requires exact duplication of materials shapes and cut ISO standards help make that happen.

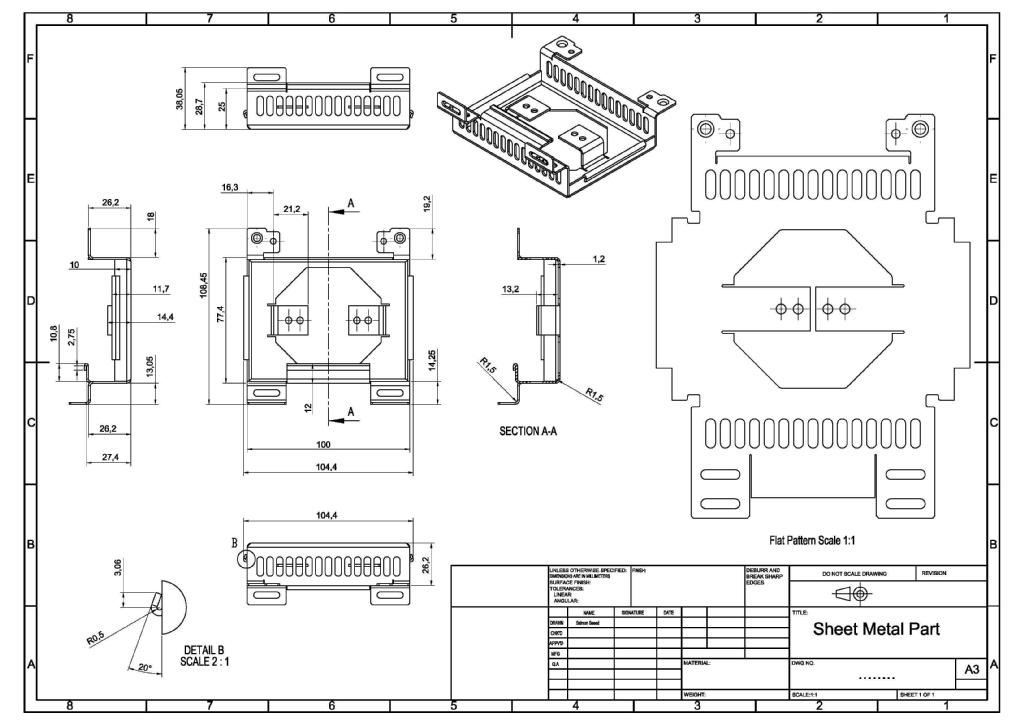

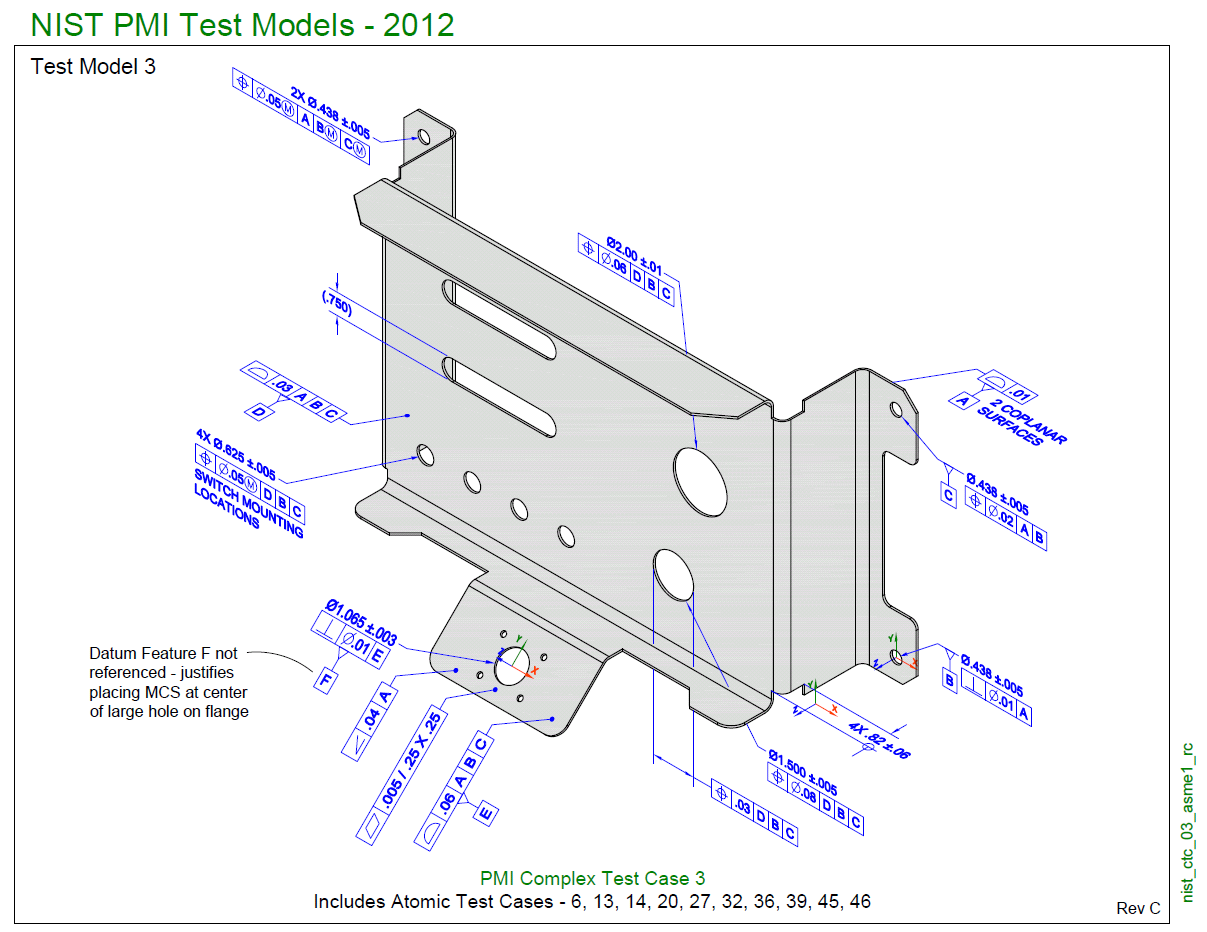

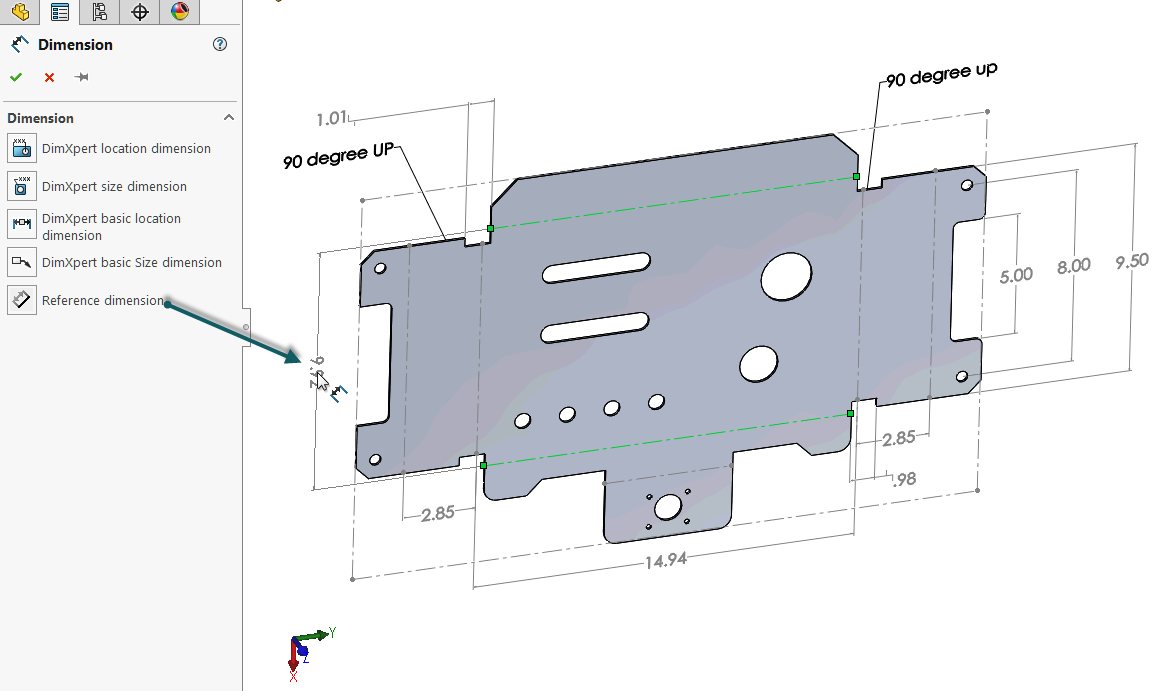

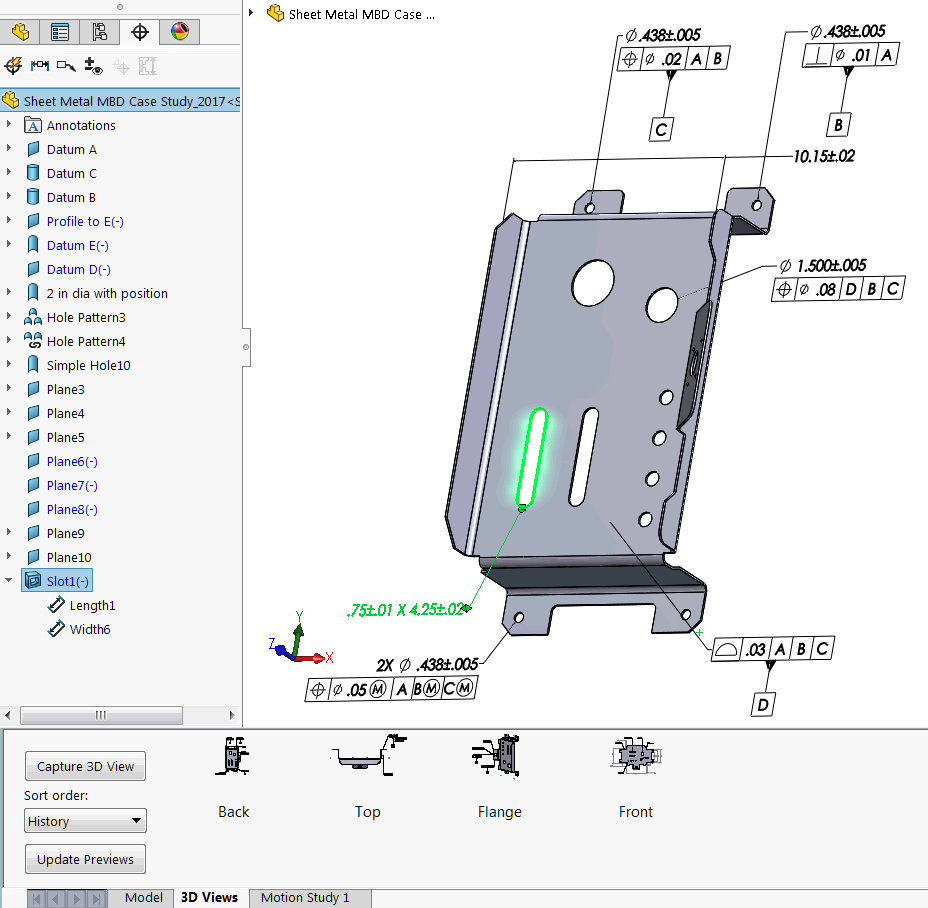

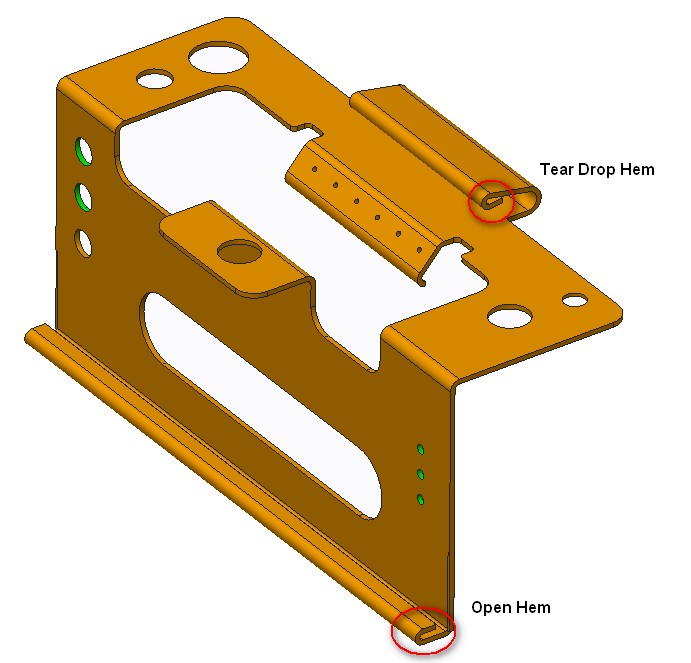

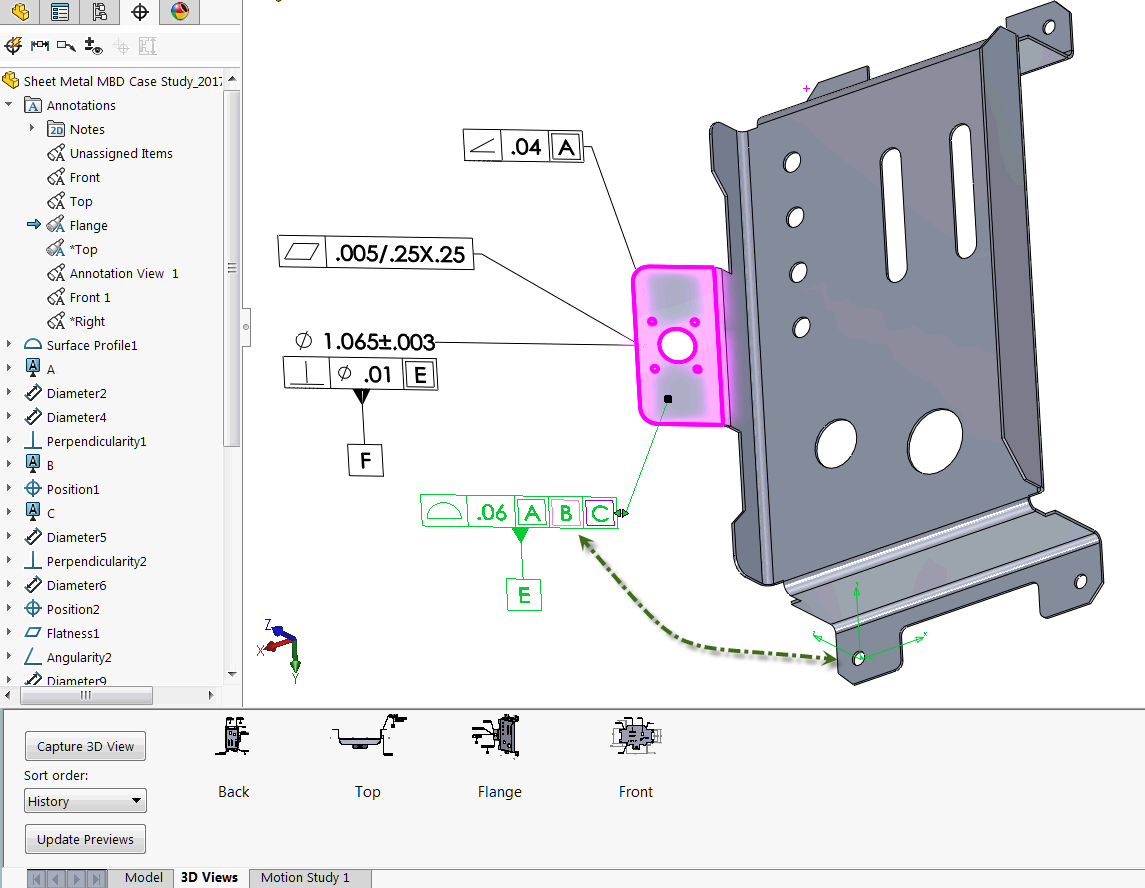

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Freelance Sheet Metal Design Services For Companies Cad Crowd

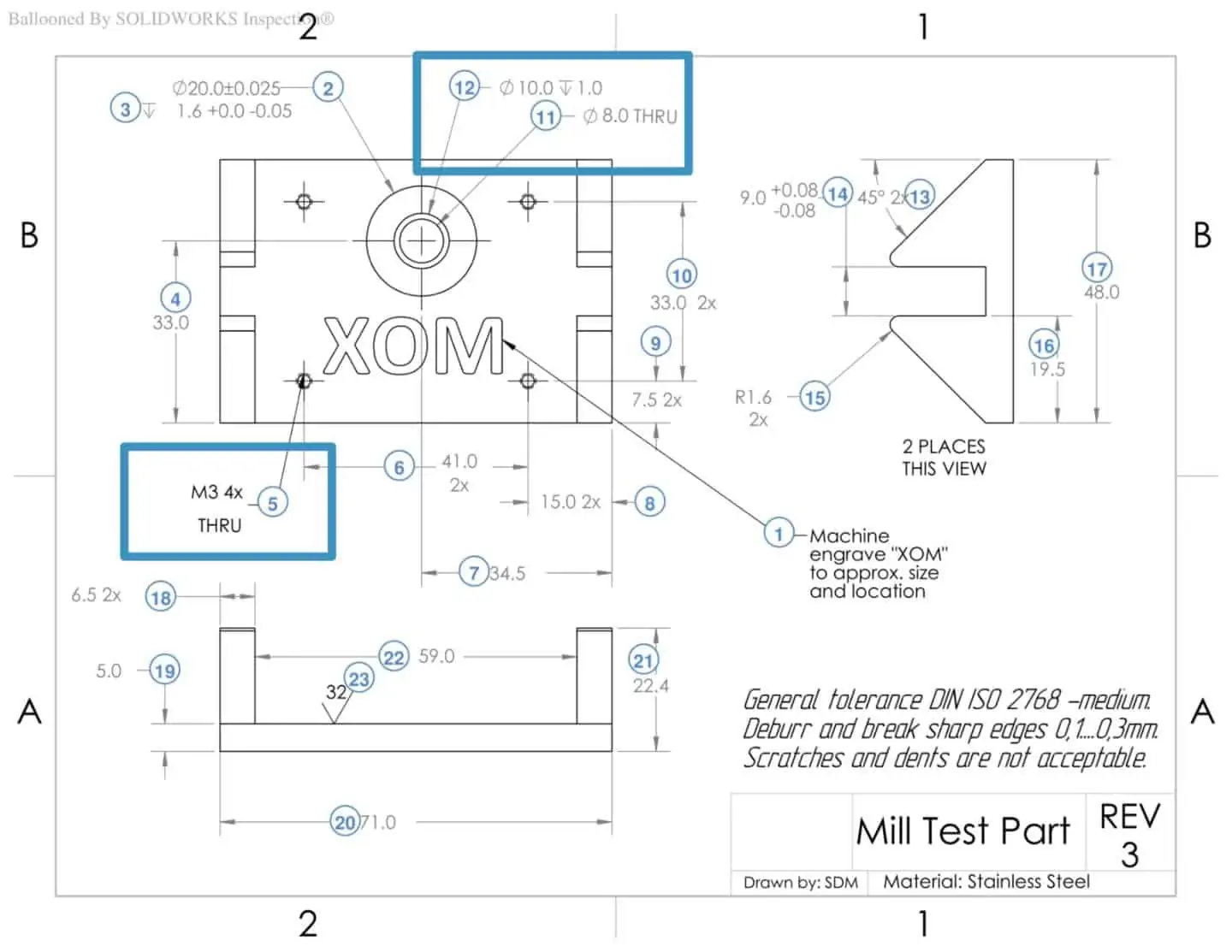

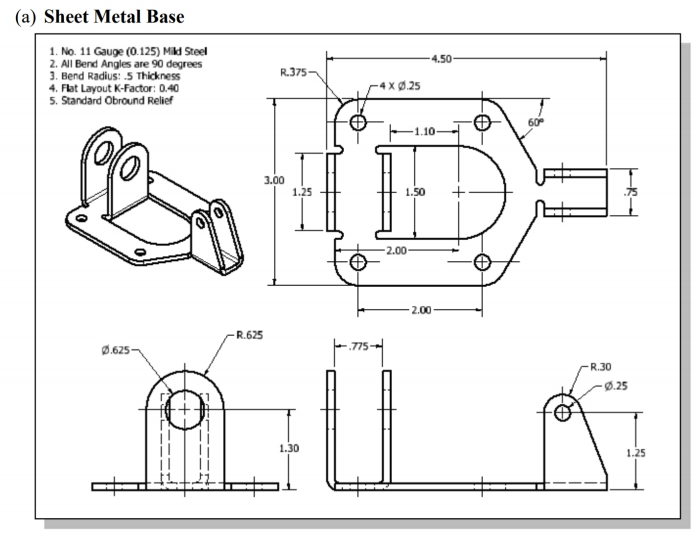

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

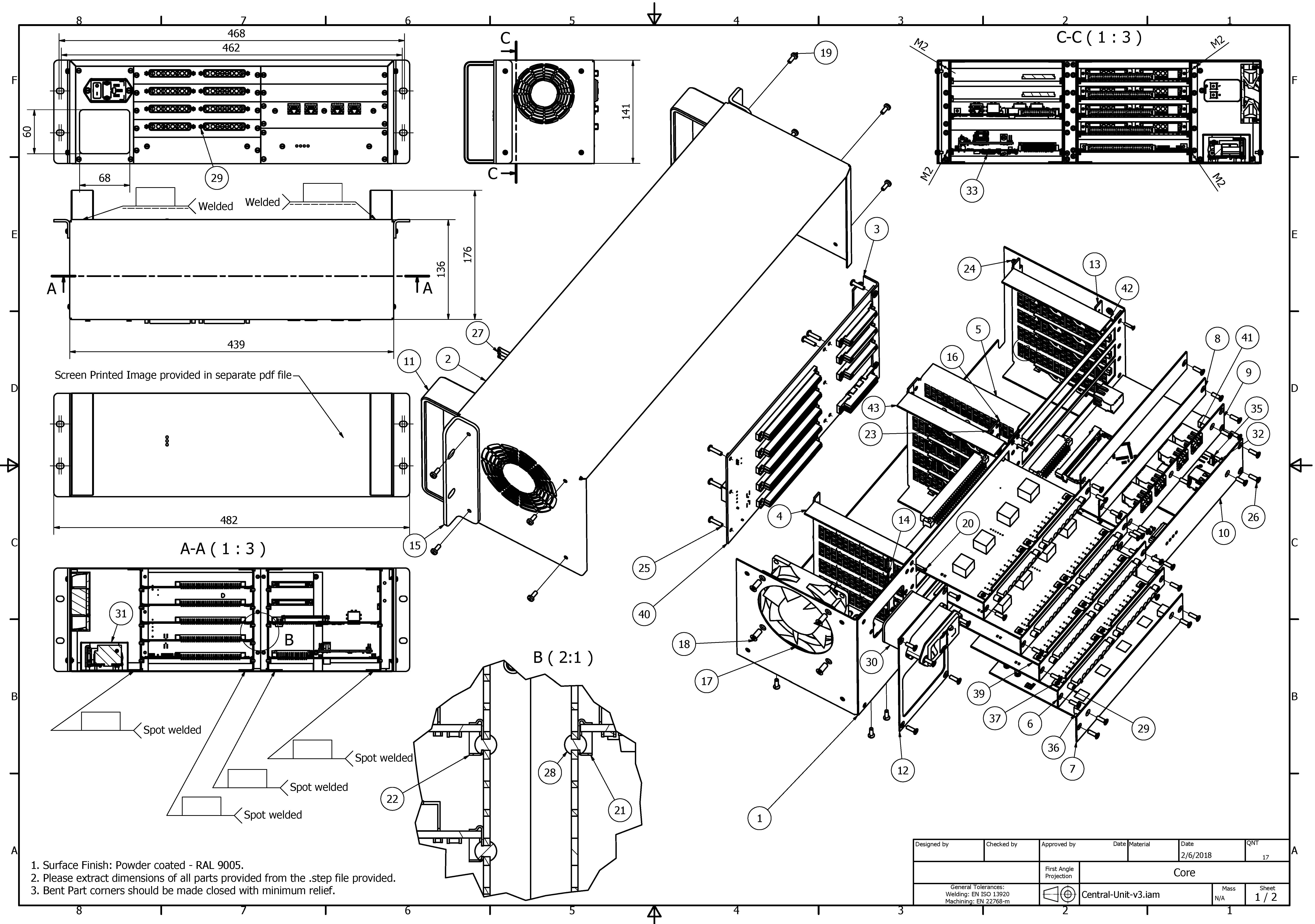

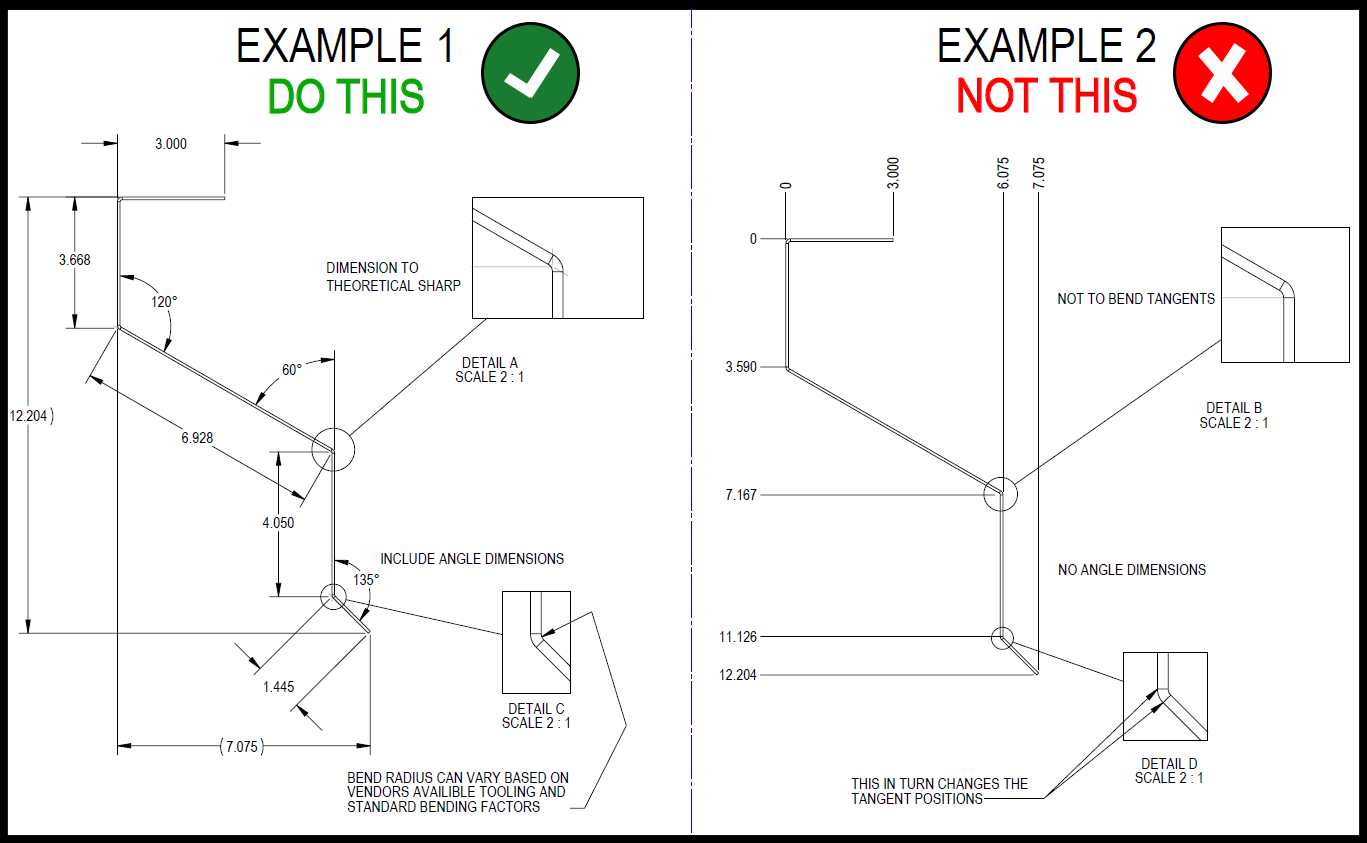

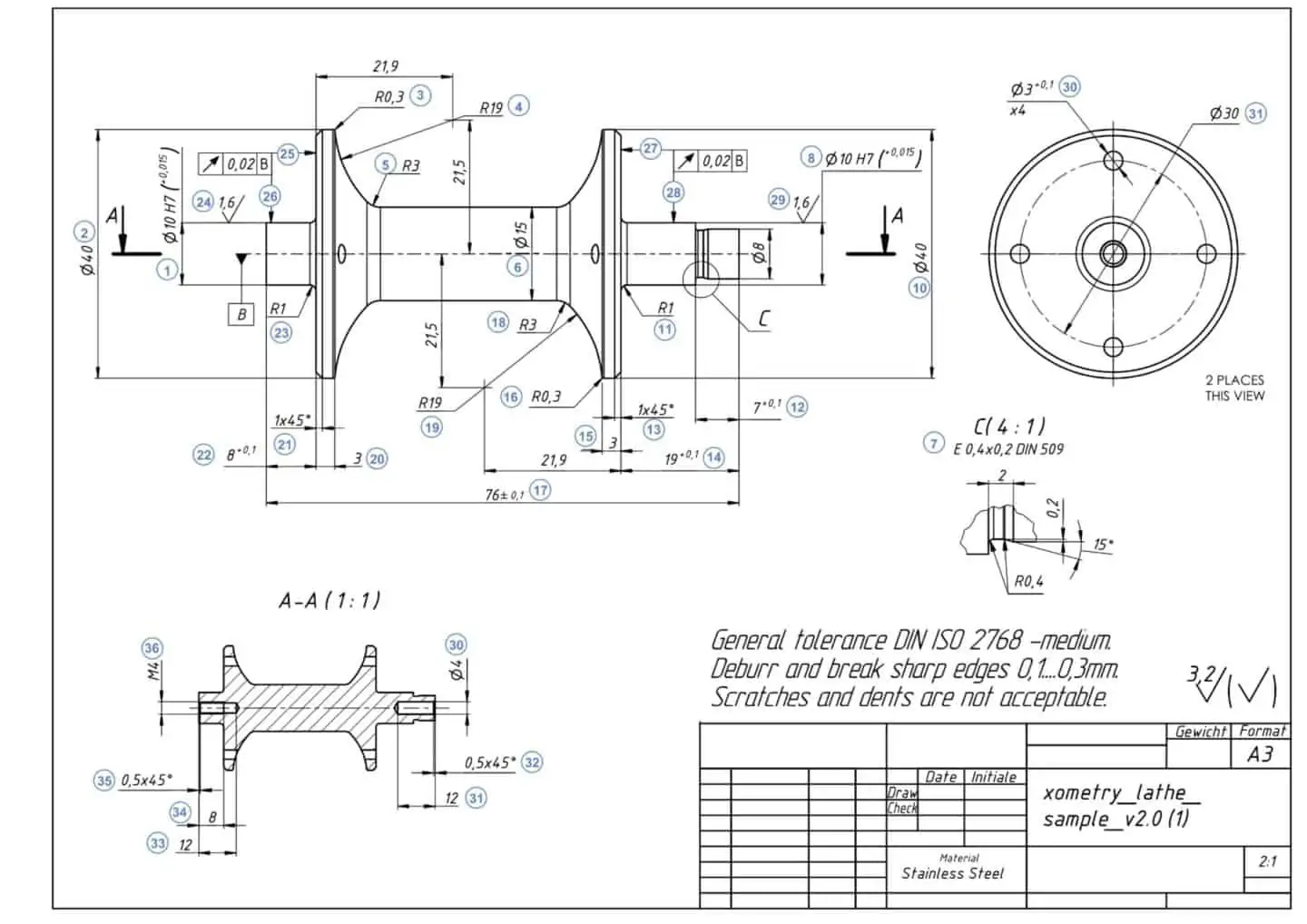

How To Prepare A Perfect Technical Drawing Xometry Europe

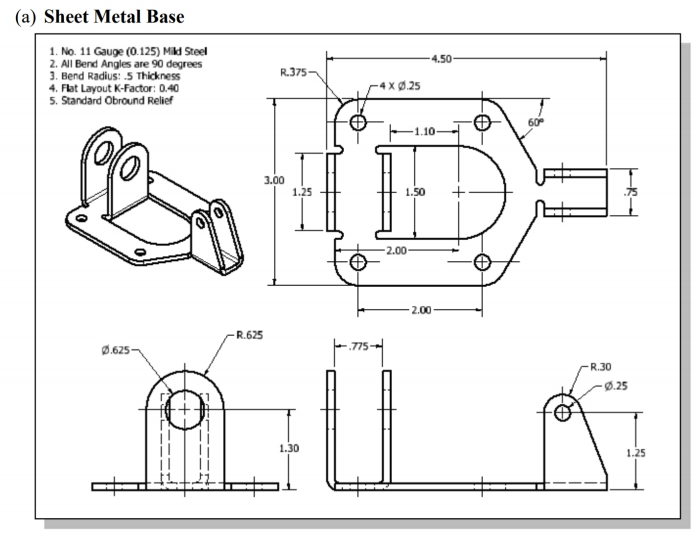

Dimensioning For Ease Of Manufacturing

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Present The Mbd Data Of Sheet Metal Parts Engineers Rule

Sheet Metal Design Guidelines Dfmpro

Solved A Sheet Metal Base 4 50 1 No 11 Gauge 0 125 Chegg Com

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Prepare A Perfect Technical Drawing Xometry Europe

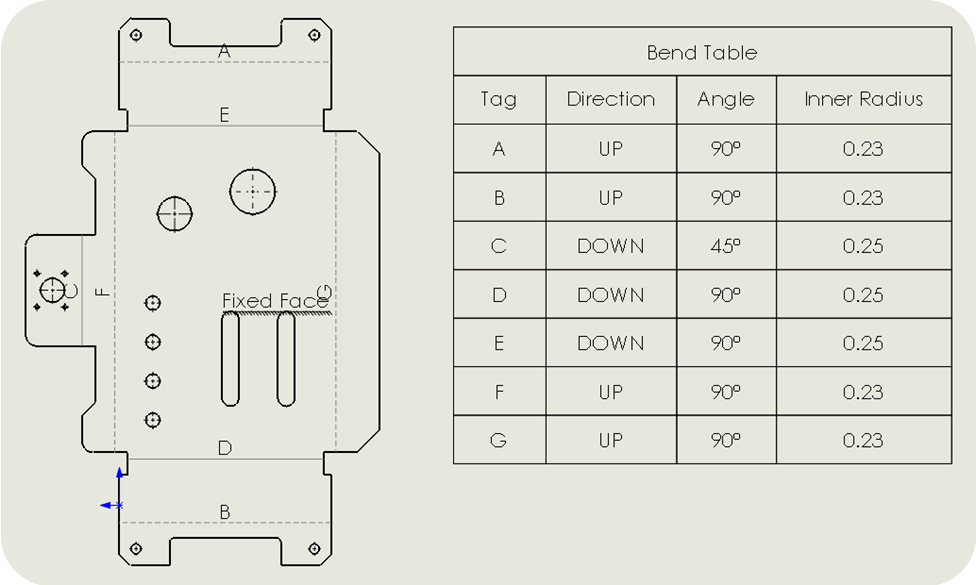

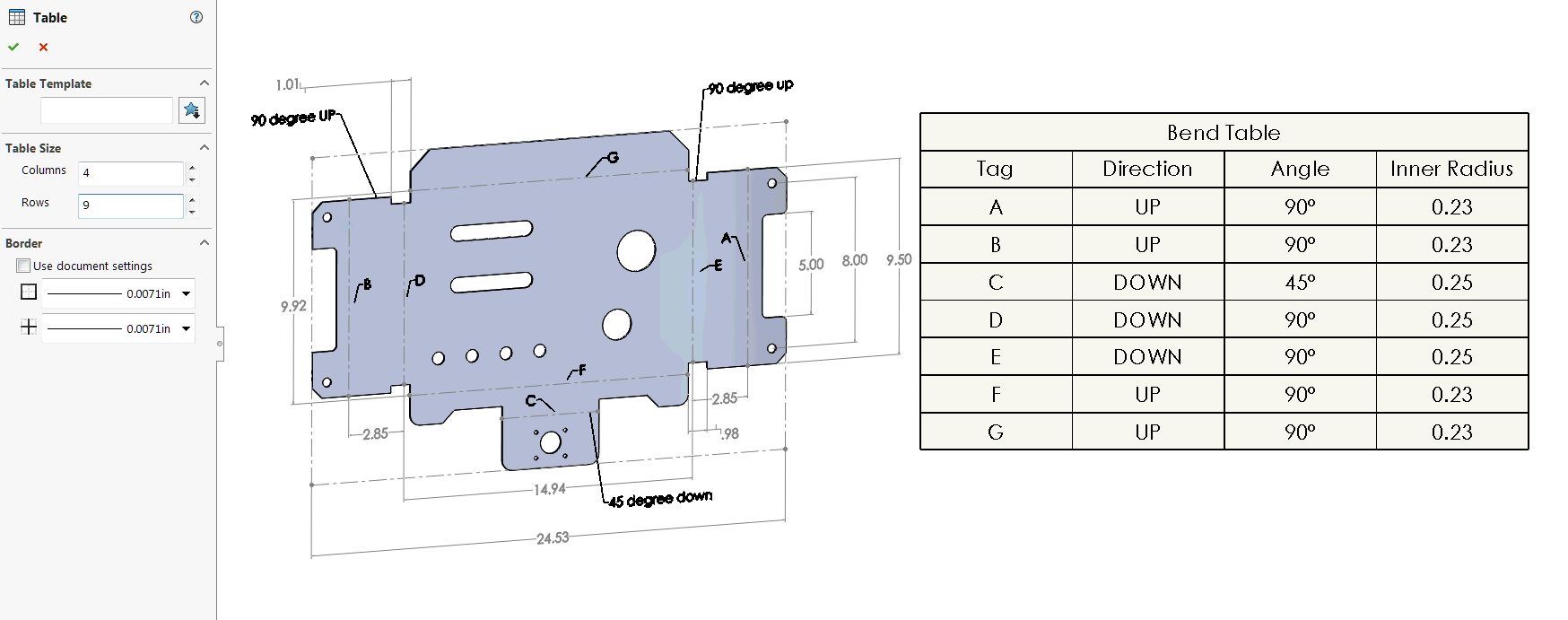

Solidworks Sheet Metal Drawing Tutorial Bend Line Flat Pattern Unfolded Bend Table Punch Table Youtube

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Sheet Metal Drawing Sheet Sheet Metal Drawing Drawing Sheet Sheet Metal